-

- Appearance: A colorless liquid with a characteristic odor

- Solubility: Insoluble in water but soluble in most organic solvents

- Reactivity: Reacts violently with oxidants and strong bases, and forms esters with acids

- Uses: Used as a plasticizer, in the production of coatings and lacquers, and as a defoamer for varnishes, paints, and ceramics

-

- It has good

solubility

- Can be used as solvent in coating, lacquer.

- can be used as solvent printing ink, adhesive, lea theroid,

nitrocellulose, etc.

-

- HDPE FI0851P is a high molecular weight.

- High density polyethylene resin.

- Designed for blown film applications.

-

- Low Density Polyethylene (LDPE) grade.

- Suitable for general-purpose packaging.

- Thin shrink film, lamination film, produce bags.

-

- M500026T is a Linear Low Density Polyethylene grade

- With narrow molecular weight distribution suitable

for injection molding applications.

-

- Main raw material for the manufacture of melamine formaldehyde resin

- Widely applied to such industries as timber processing, decorative paneling

- Fire retardants, top-grade paints & coatinHigh-performance cement water reducers

-

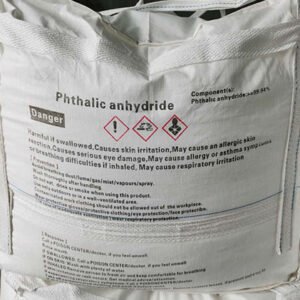

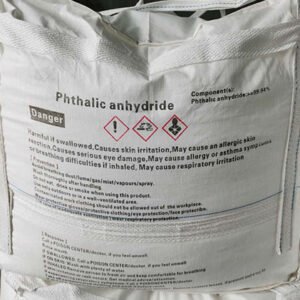

- Phthalic Anhydride is made from phthalates or naphthalene.

- The most common method

involves the catalytic oxidation of o-xylene with air over a vanadium pentoxide catalyst at high

temperatures.

- Another method

involves the catalytic oxidation of naphthalene with air over a metal oxide catalyst.

-

- PVC compounds also known as a dry blend

- PVC compounds can be

formulated for flexible materials using plasticizer,

- UPVC granules pellets are widely used for manufacturing unplasticized polyvinyl chloride pipe

fittings.

-

- Additives: Improve impact resistance and flexibility

- Plasticizers: Improve impact resistance and flexibility

- Fillers: Modify physical properties and reduce costs

- Pigments: Color the compound

-

- General-purpose plastic in the world.

- Used in building materials, industrial products.

- Used in daily necessities, floor leather.

- Used in floor tiles, artificial leather, pipes, wires etc.

-

- Uses in Paints and Coatings, Inks industries.

- Uses in Masterbatch, PVC, Adhesives, and Construction chemicals etc.

- There are two manufacturing processes of TiO 2 .

- i) Sulphate Process, ii) Chloride Process.